JSR Earthing Solution Chemical Earthing to Ensure Optimum Electrical Safety

Today, electrical safety is seen as the utmost requirement in domestic households as well as in corporate. Our team at JSR Earthing Solution understands this demand and offers the most convenient, effective and suitable chemical earthing solutions for individual clients and corporate customers. We are Best Earthing Manufacturer & We serve Gi plate earthing Suppliers in Gujarat.

Chemical Earthing

Why Earthing

The main reason for doing earthing in electrical network is for the safety. When all metallic parts in electrical equipments are grounded then if the insulation inside the equipments fails there are no dangerous voltage present in the equipment case. if the live wire touches the grounded then the circuit is effectively shorted and fuse will immediately blow. When the fuse is blown then the dangerous voltages are away. We also sell Gi and copper Earthing Strip supply in Gujarat.

Purpose of Earthing :

(1) Safety for Human Life / Building / Equipments : -

- – To save human life from danger of electrical shock or death by blowing a fuse i.e.

- -To provide and alternative path for the fault current to flow so that it will not endanger the user.

- – To protect building. machinery & appliance under fault conditions.

- – To ensure that all exposed conductive parts do not reach a dangerous potential.

- – To Provide safe path to dissipate lighting and short circuit currents.

- – To provide stable platform for operation of sensitive electronic equipments i.e.

- – To maintain the voltage at any part of an Electrical system at a known value so as to prevent over current or excessive voltage on the appliances or equipments.

(2) Over Voltage protection : -

- – Lighting line surges or uninternationall contact with higher voltage lines can cause dangerously high voltage to the electrical distribution system.

- – Earthing provides an alternative path around the electrical system to minimize damages in the System.

(3) Voltage stabilization:-

There are many sources of electricity Every transformer can be considered a separate source. If there were not a common reference point for all these voltage sources if would be extremely difficult to calculate their relationship to each other. The earth is the most omnipresent conductive surface. and so it was adopted in the very beginnings of electrical distribution systems as a nearly universal standard for all electric systems.

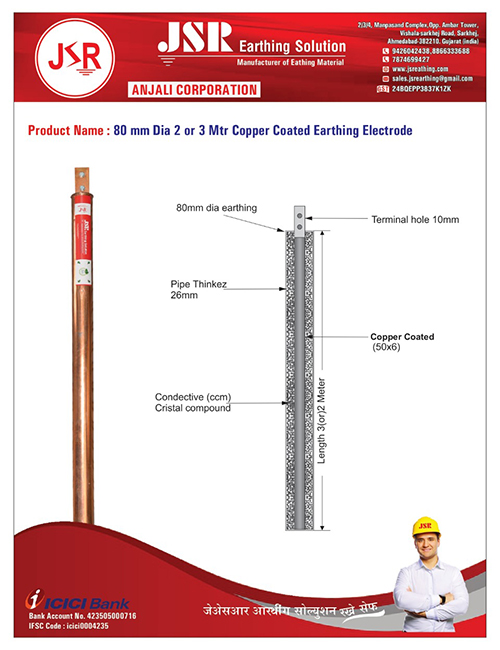

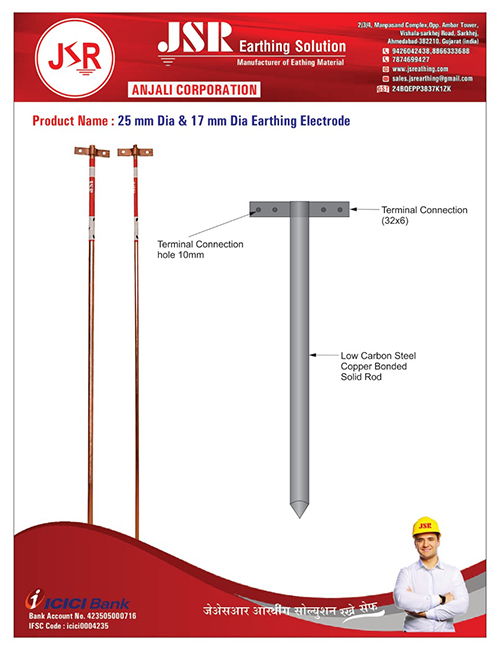

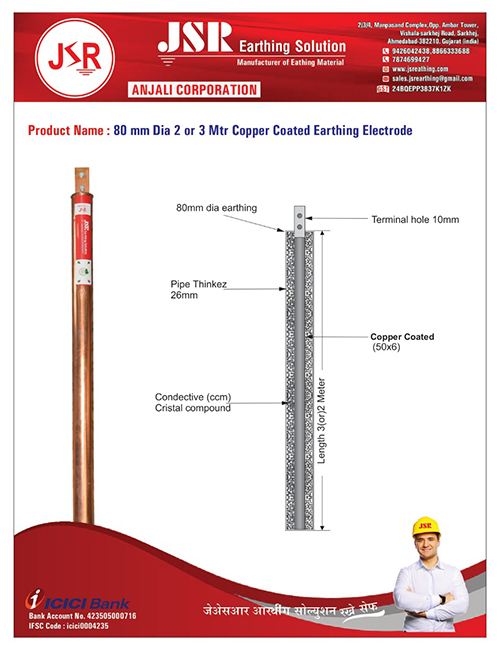

The Pipe-in-Pipe Technology concept involves two mild steel pipes : one small dia pipe is inserted in a large dia pipe. The fitted pipes are subjected to hot dip galvanization: 80-100 micron on the outer electrode. The space inside the electrodes are filled with a specially developed high conductive and anti corrosive mixture called Crystalline conductive Mixture.

For uniform distribution of fault current, an earthing electrode must be cylindrical in shape. The surface being circular, the distance from the center to any point is always equal. This facilities uniform distribution of fault current from electrode to earth.

The current density is highest near the electrode surface. The density should be as low as possible in the medium adjacent to the electrode with should be such as to cause the current density to decrease rapidly with in a distance from the electrode. Thus a pipe electrode has lower resistance than a plate electrode pf equal surface area.

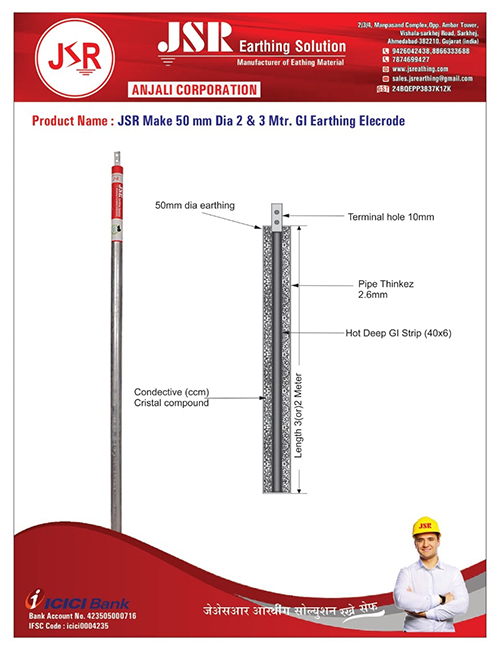

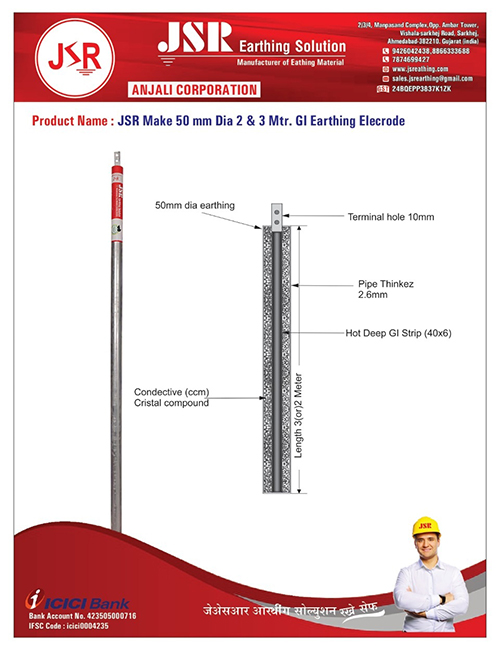

GI Earthing

The Strip in pipe technology concept involves one pipe and a flat. flat varically inserted inside from top to bottom of the pipe. Inserted flat is copper bonded for the high conductivity and longer life.

The empty space inside the electrode between pipe and flat is filled with constant conductive compound does not collapse even if outer pipe corrodes after so many years, thus there is no reduce earthing surface area for long time.

Copper Earthing

Why We Choose Back Fill Compound?

Our R & D team recommends the use of suitable ground enhancing material to further increase the qualities of the soil for better performance of the earthing systems. An ideal ground enhancing material should not have any adverse effect on the electrode material and environment. It should retain moisture around the earth pit, reduce the soil resistivity and initiate faster dissipation of the fault current. Upon adding water to the Bick Fill Compound, there is substantial swelling. These capabilities resolve the issues of the compatibility of soil-rod contact tha is crucial to the earthing system. We Give best quality backfill compound earthing wire for sale In Gujarat.

Our BFC is environment friendly compound. BFC maintains moisture withing the sphere of influence of the electrode, resulting in lower earth e resistance, which cannot be obtained from any other earthing system. BFC enhance the surrounding soil conductivity, thereby making the earthing eliale and effective

Backfill Chemical Compound: most efficient in retaining ground moisture

- It is an Idal Back Feel Compound

- IT Reduces The Soil Resistivity And Helps To

- Retain Moisture

- Best For Normal Soil Conditions

Back Fill Compound

JSR Earthing Solution – Earthing System

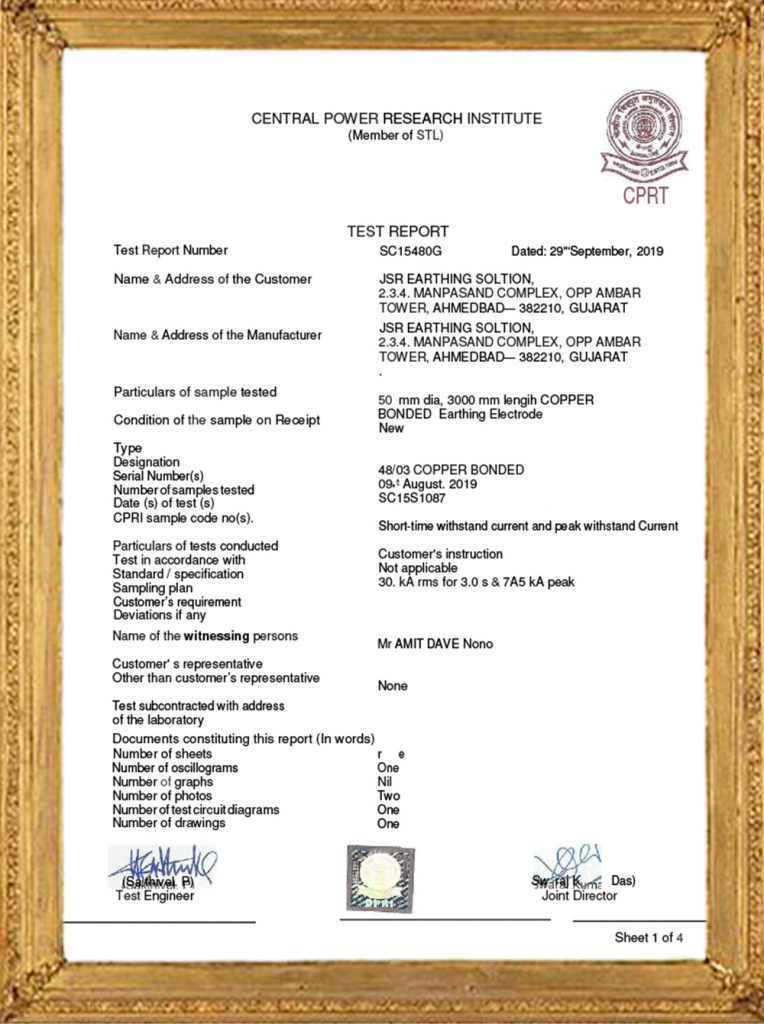

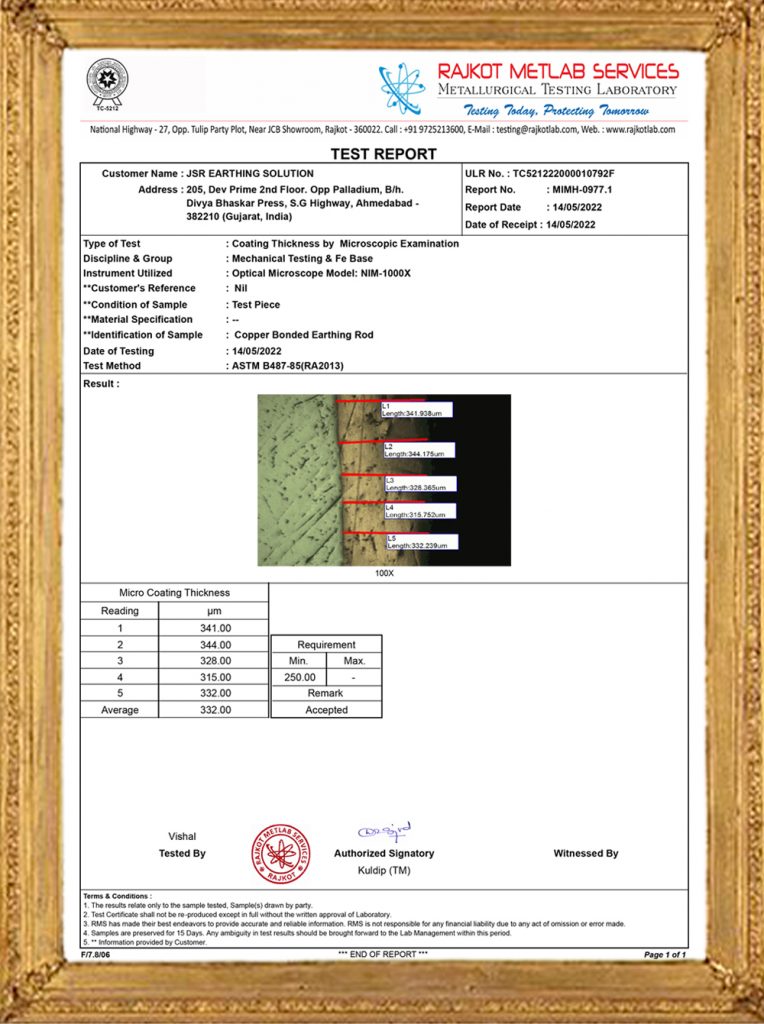

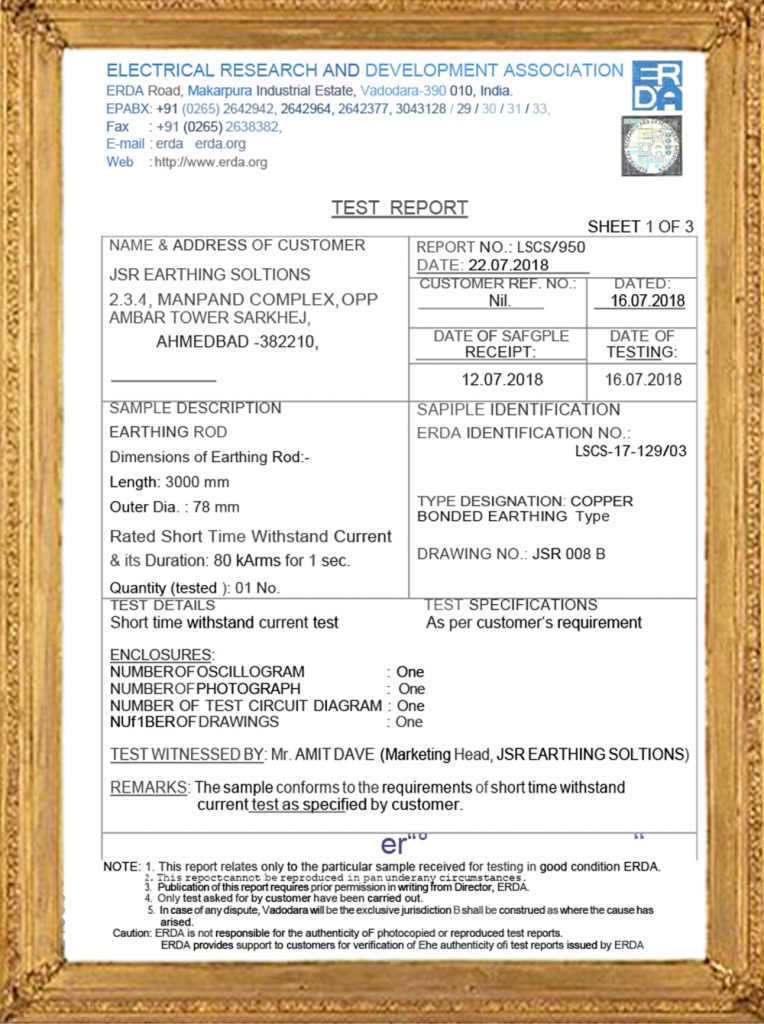

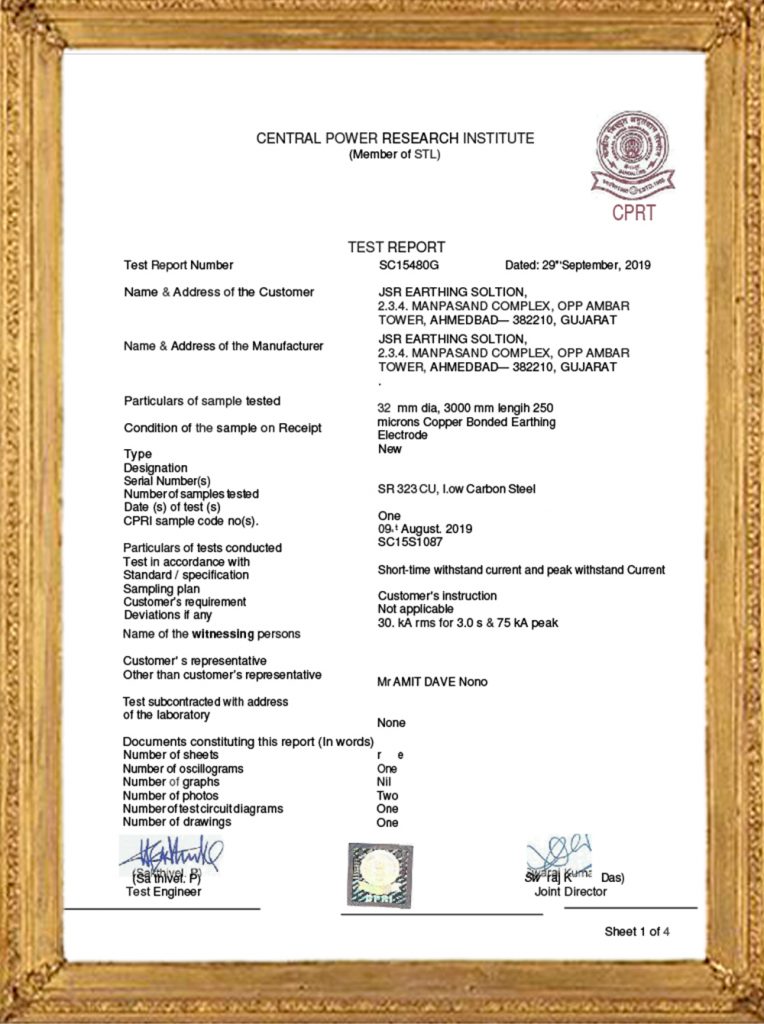

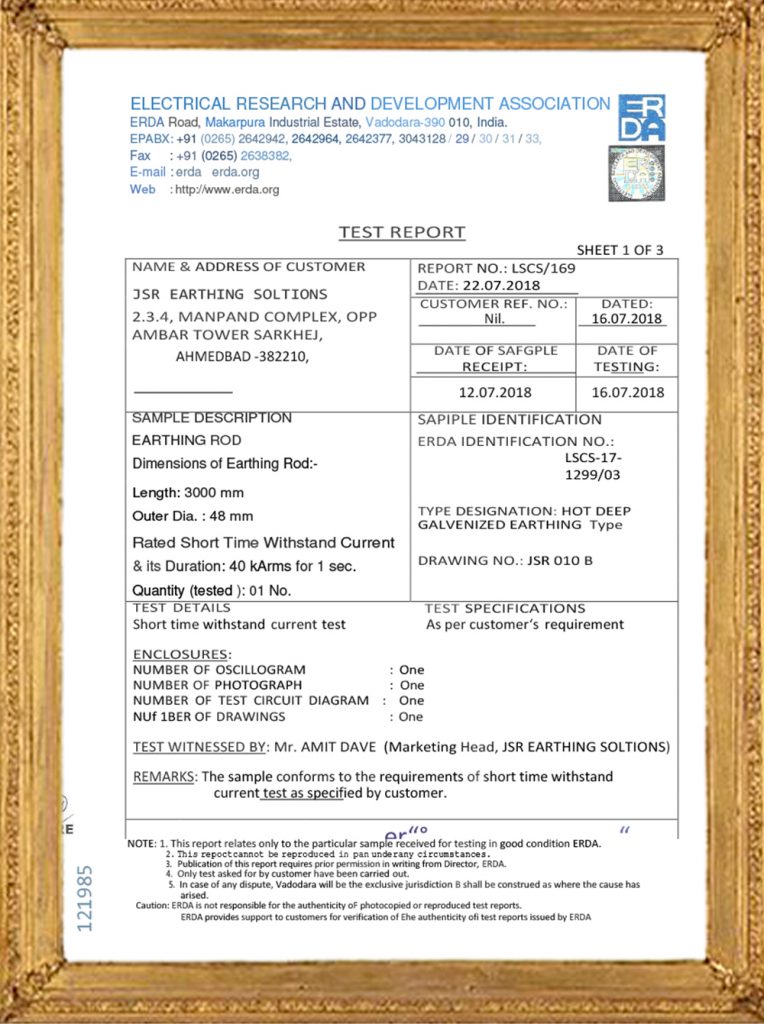

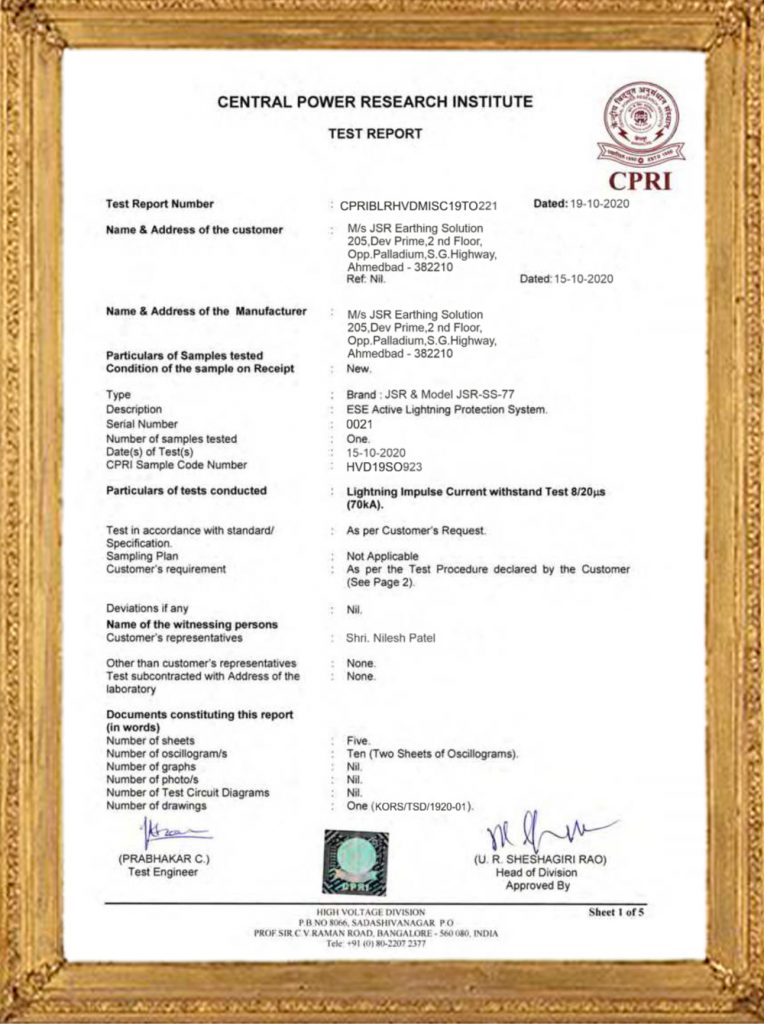

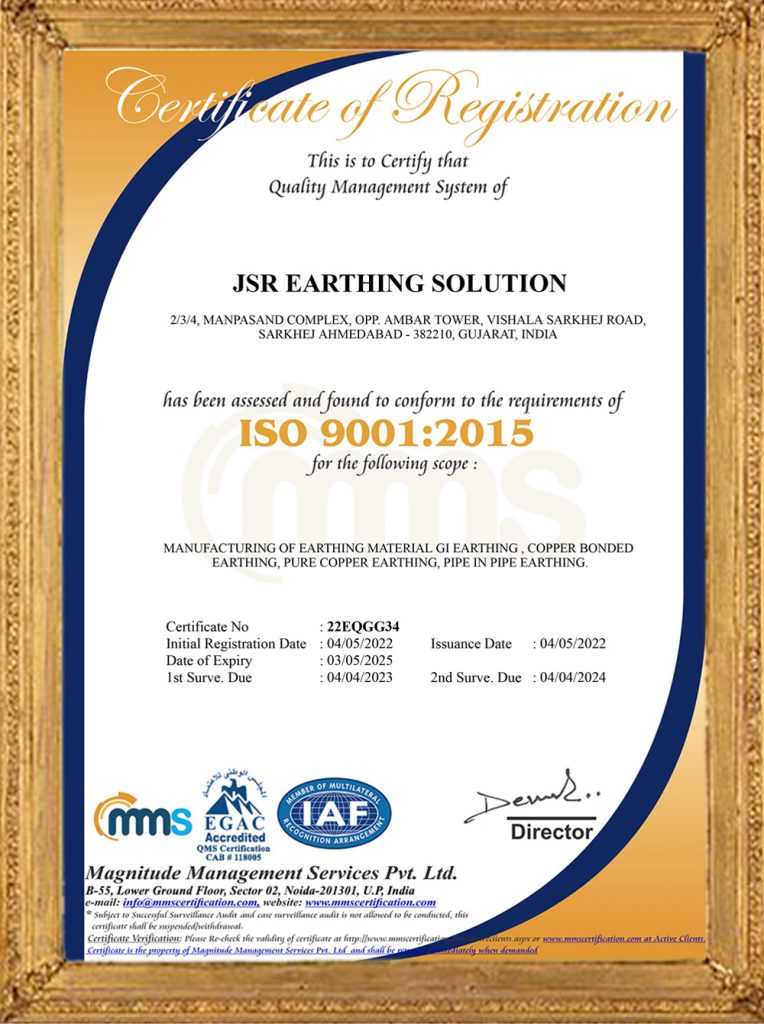

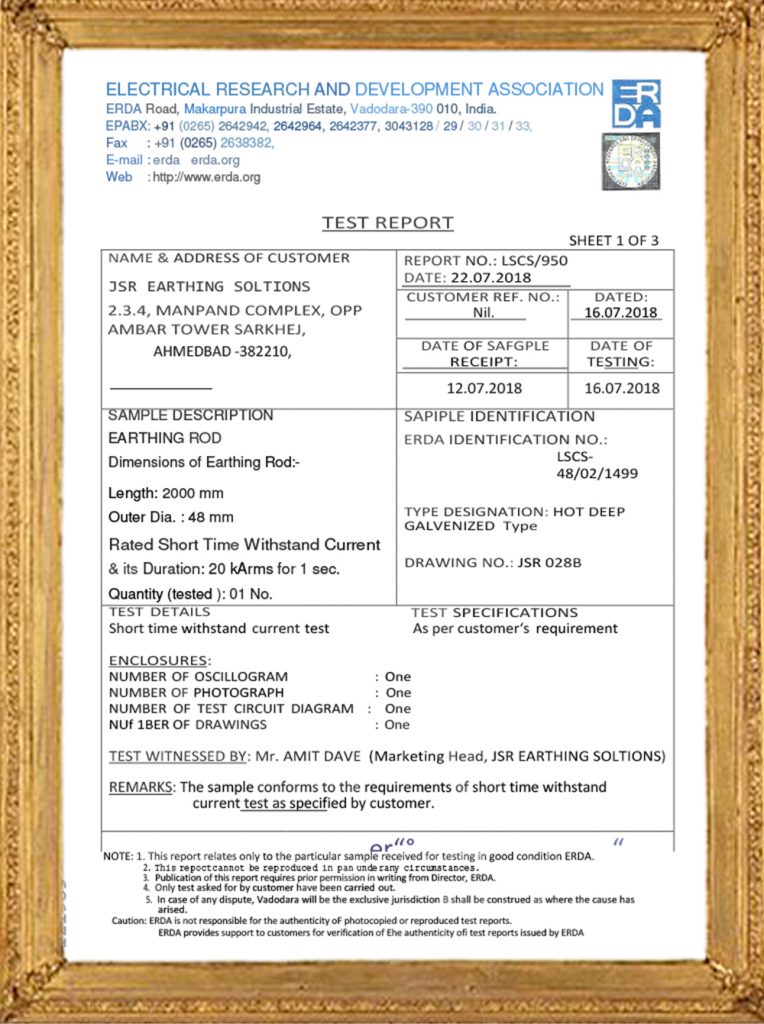

Our Certificate's